In addition to relying on the prosperity of the market, Yuli's advertising pvc light box cloth is also very important for the company's advertising to be aggressive. Nowadays, the requirements of advertisers are getting higher and higher, and new advertising patterns are emerging in endlessly. The rapid development of China's advertising industry is early or accepting changes. The domestic advertising production industry has always been synchronized with foreign countries, from the initial neon lights to light box stickers and inkjet advertising.

The reason why inkjet has won the attention and favor of the industry

There are no more than three reasons:

First, the operation and control are simple, and the production time is fast;

Second, it is extremely convenient to install and carry;

Third, the advertisement page has a vivid effect, which can create an extraordinary effect.

These three advantages are extremely suitable for the current social rhythm of the ever-changing information age. The most important substrate for inkjet printing is light box cloth.

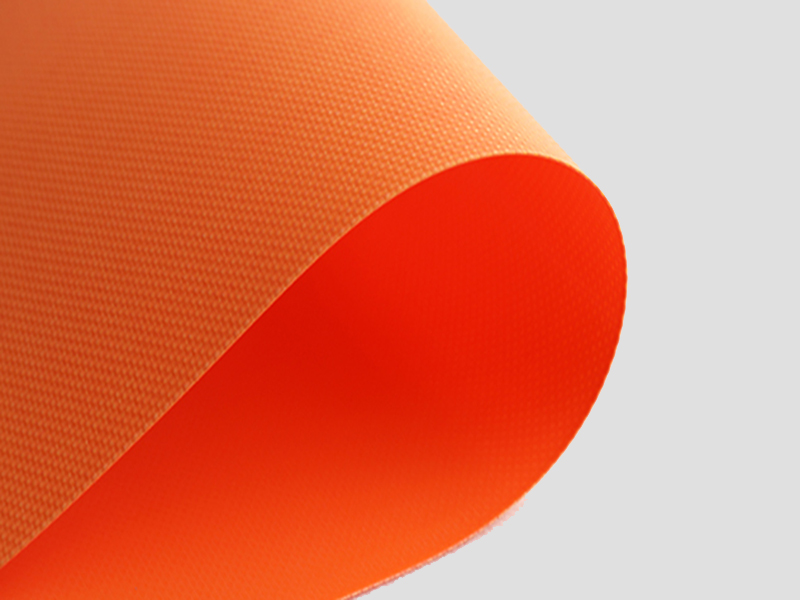

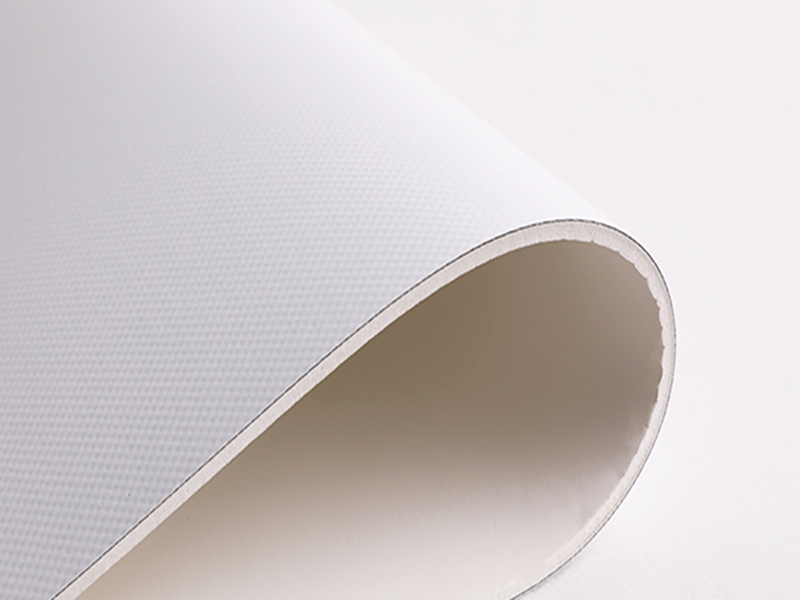

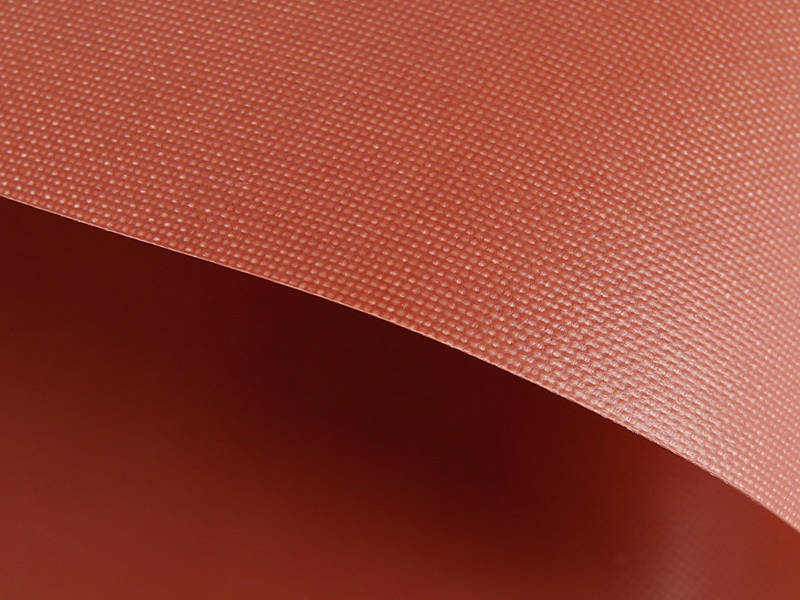

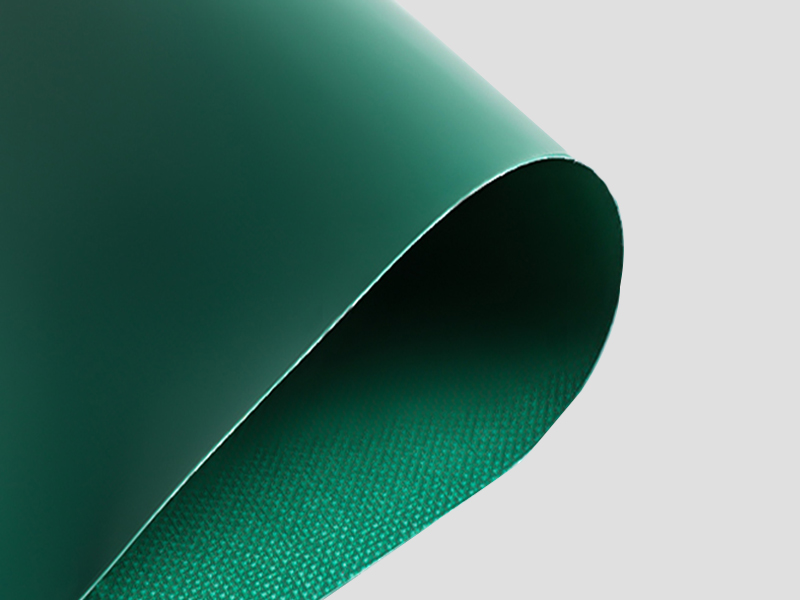

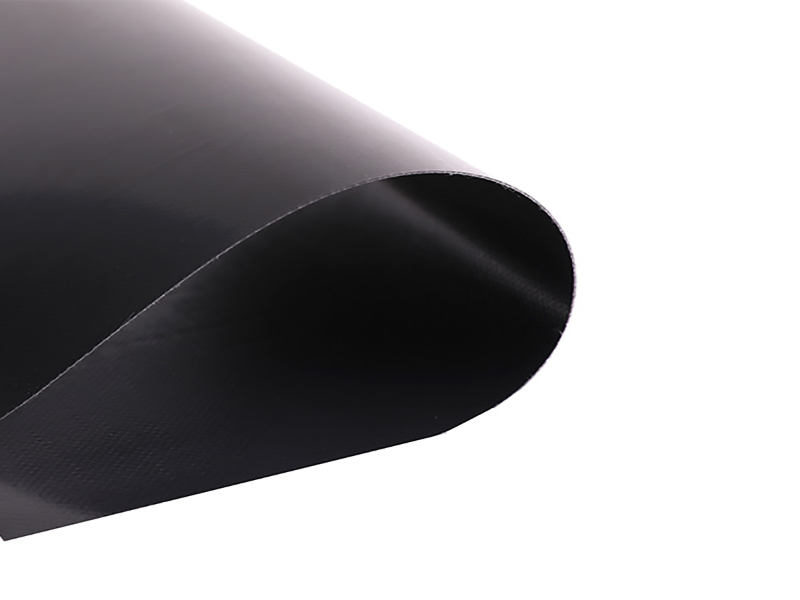

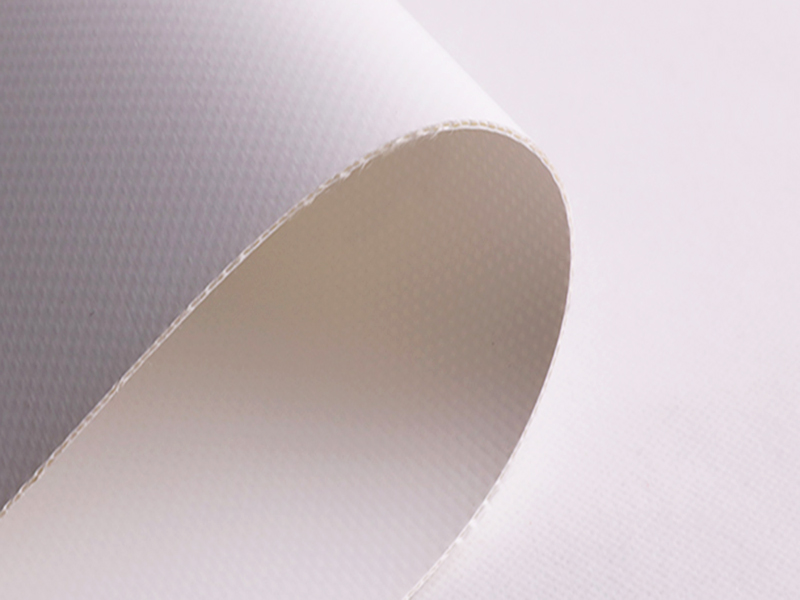

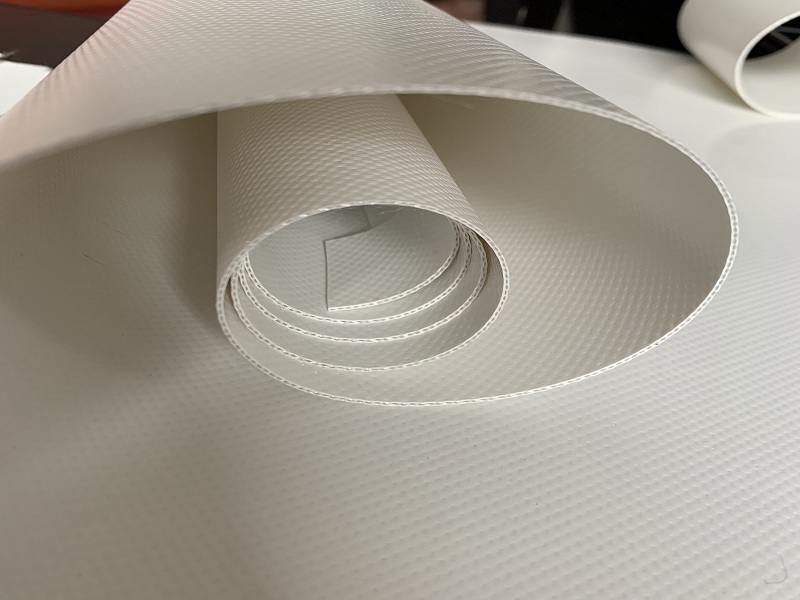

The light box cloth is made of PVC material and net-shaped light guide fiber. It has good flexibility, uniform light transmission, easy to divide, splice, consignment, and simple outdoor installation. It is especially suitable for color printing. According to the requirements of outdoor use, the light box cloth can achieve the effects of waterproof, mildew resistance, olefin resistance, cold and heat resistance, and UV resistance. Because the light box cloth has strong typhoon resistance, it is especially suitable for making large outdoor advertising signs. At present, 95% of the large color inkjet light box screens in the Chinese market use light box cloth as the substrate.

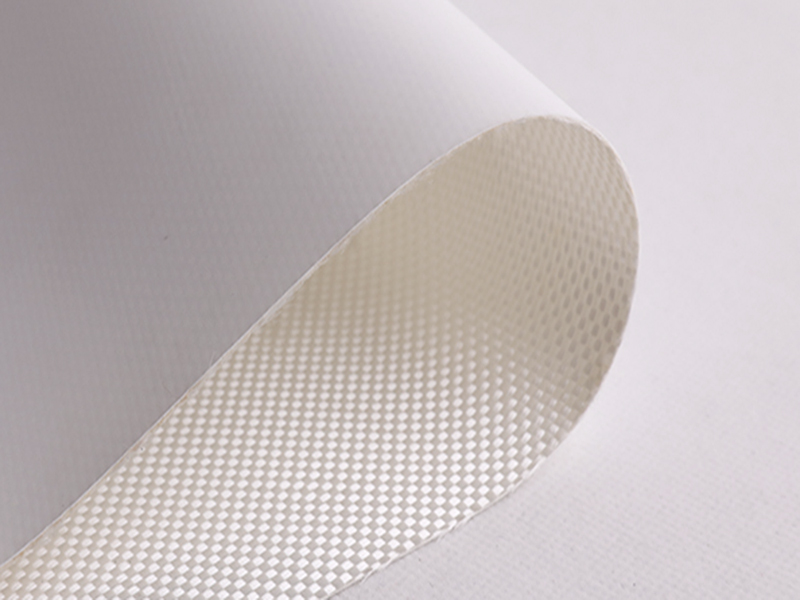

According to the light transmittance and the position of the light source, the light box cloth is divided into three types: rear light box cloth, front light box cloth and grid cloth.

Post-lighting light box cloth is used to make post-light source light boxes, and its light transmittance is generally between 25% and 35%. This kind of light boxes are mostly medium and small, and they are mostly used to make roadside light boxes, store door light boxes and indoor publicity light boxes. Generally, the area is small, no more than 100 square meters.

The front lighting light box cloth is used to make the front light source light box, and its light transmittance is generally between 5% and 10%. This type of light box is more resistant to typhoons, so it is often used to make large outdoor light boxes, such as building billboards, highway side light boxes, and urban Optimus Prime light boxes. At present, large-scale outdoor light boxes between 100 and 400 square meters in China mostly use this kind of light cloth.

The grid cloth is designed and made according to typhoon climate areas such as Taiwan and Fujian. Because the surface of this material is densely arranged with many meshes, which can make the wind pass through the surface of the light cloth, it can greatly reduce the pressure of the typhoon on the light box and make the picture more Long-term outdoor use effect. Because of this feature, grid cloth is mostly used to make super-large signage advertisements and architectural advertisements.