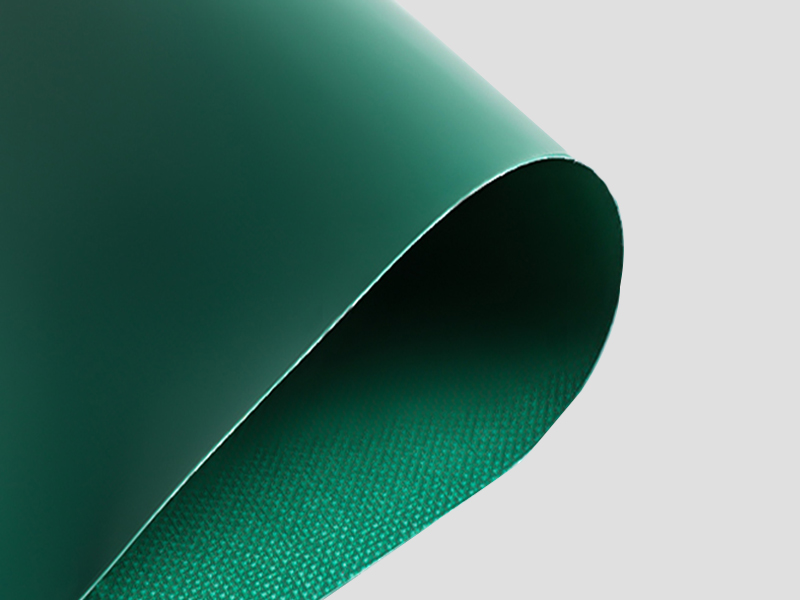

PVC light box cloth is a kind of light box sign fabric composed of two layers of PVC and a layer of high-strength grid cloth, which can be divided into two types: inner lightening and outer lightening. The main production methods include knife coating method, calendering method, and pasting method (melting method).

The key points of quality identification of pvc light box cloth: thickness, tensile strength, ductility, weather resistance, light transmittance, flame retardancy, peeling degree, flatness, such as ink absorption, color reproduction and so on.

Pvc light box cloth is divided into three types according to the production process: knife-scraping light box cloth, calendering light box cloth and pasting legal light box cloth.

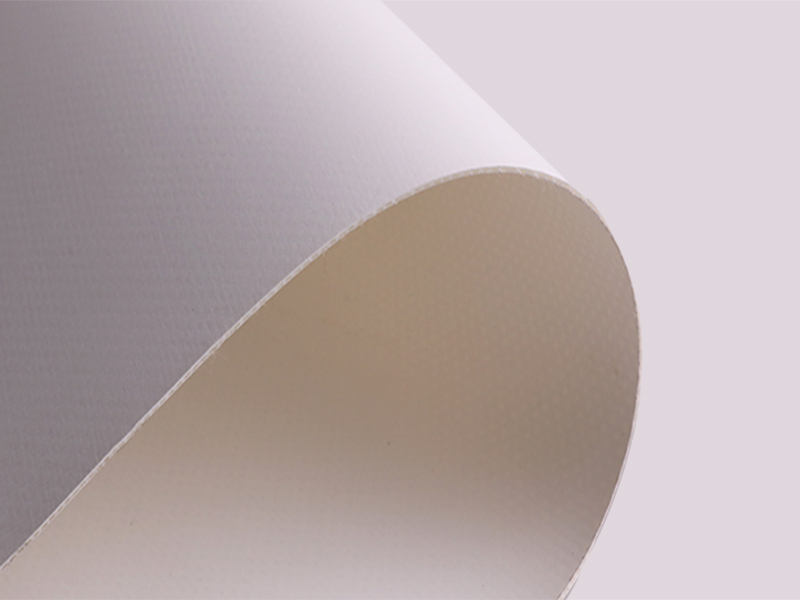

Knife scraping method: The knife scraping method light box cloth process is to apply the liquid PVC slurry evenly on the front and back sides of the base cloth with a number of reverse scrapers, and then use a drying process to make it completely integrated into a whole, and then cool and shape. It is characterized by strong anti-permeability, tensile strength and anti-peeling ability. Because the knife scraping method is a whole, the peeling phenomenon can be eliminated, and the strength of the joint can be greater than the product itself through welding. At present, the light box fabric width of this technology can reach 5 meters. Due to the complicated production process and the relatively expensive production equipment, such products are mainly imported in the Chinese market, and the price is relatively high. The most representative ones are ULTRALON made in Germany, UNIFLEX made in Korea and SIOEN made in Belgium.

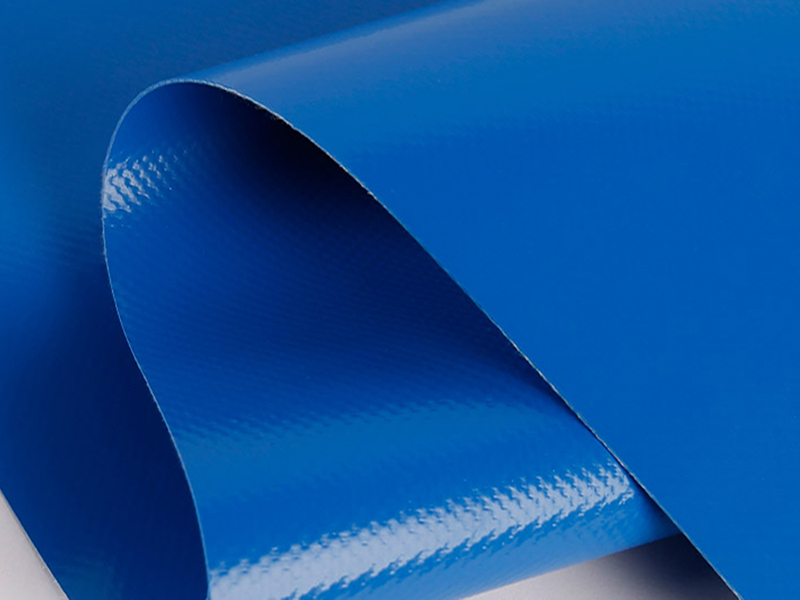

Calendering method: The calendering method is to fully stir PVC powder and liquid plasticizers and other raw materials, and then bond with the base fabric into a whole under the pressure of a high-temperature hot roller. Its characteristic is that the surface is flat, and the light transmission is even, and it has advantages on the inner lighting lamp cloth. However, due to the limitation of equipment, the width is generally not more than 3 meters. Both the 645 and 945 light box cloths developed by 3M in the United States are produced by this process; the Lexi light box cloth developed by LG in South Korea is also a representative of this type of process.

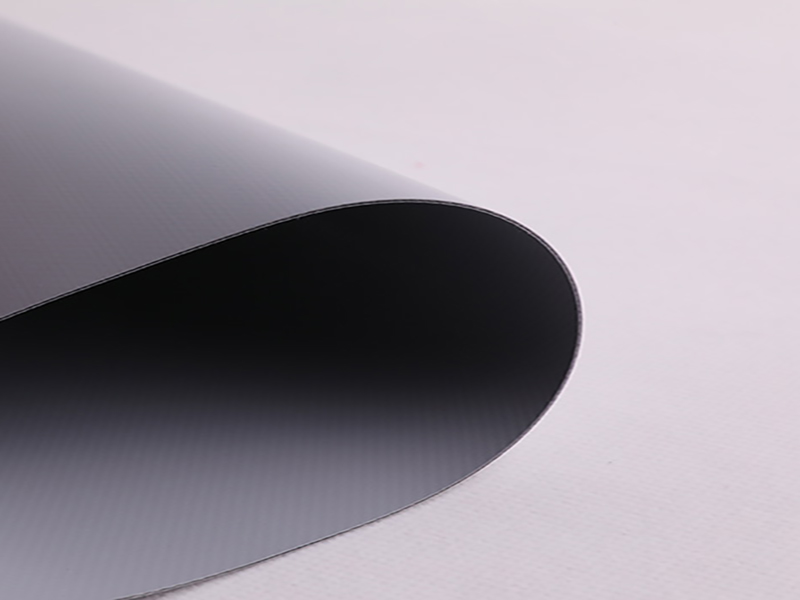

Pasting method: Pasting legal light box cloth is to form the upper and lower layers of the PVC film, which is heated and bonded with the light guide fiber net in the middle under the pressure of the heat roller, and then cooled to form. The biggest feature of this process is its excellent ink-jet ink absorption and strong color expression. Therefore, with the rise of large-scale inkjet printing, it also brings infinite vitality to this type of light box cloth. At present, the market share of this kind of light box cloth in China has exceeded 70%.