What are the properties of PVC tarpaulin? Tent and tarpaulin products can protect against rain, heat and cold. Therefore, such products are required to have certain performance.

(1) Basic performance requirements of tarpaulin

Considering the various uses of tarpaulin, the general requirements that should be met are:

(1) Light weight, easy to fold, easy to carry and operate;

(2) High strength, wear resistance and long service life;

(3) Good waterproof and breathable performance, anti-condensation on the inside;

(4) Acid and alkali resistance, mildew resistance, and corrosion resistance;

(5) Good weather resistance, flame retardant and fireproof; (6) No wicking effect, no moisture conduction phenomenon.

Tarpaulins generally require the "three-proof" function. That is, waterproof, fireproof (flame retardant), and mildew proof.

(2) Main performance indicators

In the specific product design or use, the following performance indicators of the tarpaulin should be considered.

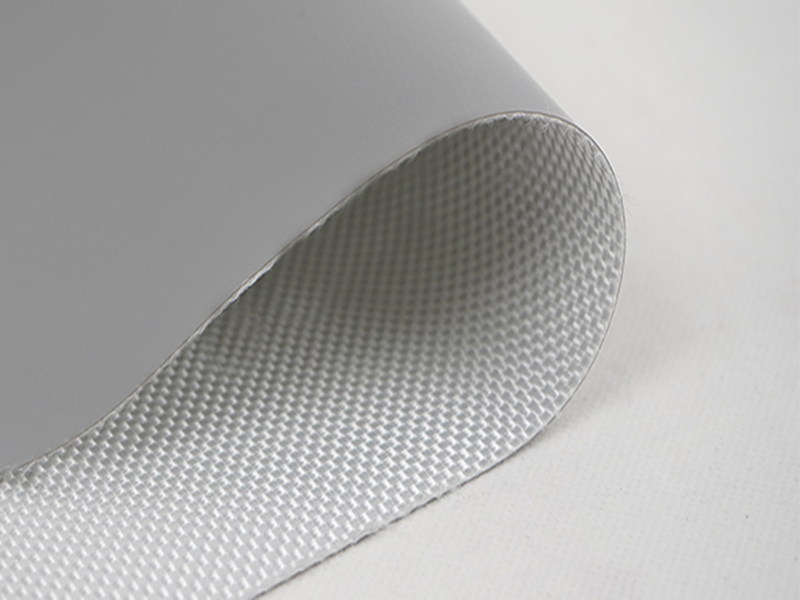

1. Breathability: The breathability of tarpaulin must be considered, especially for military tents. The influence factors of breathability include base fabric structure, density, material, type of waterproof finishing agent, resin adhesion, etc. As the amount of resin adhesion increases, the air permeability of the tarpaulin decreases. Of course this is related to the finishing agent used. Generally, most air-permeable tents are made of cotton, vinylon, lacquer and other short-woven fabrics finished with paraffin wax or acrylonitrile resin.

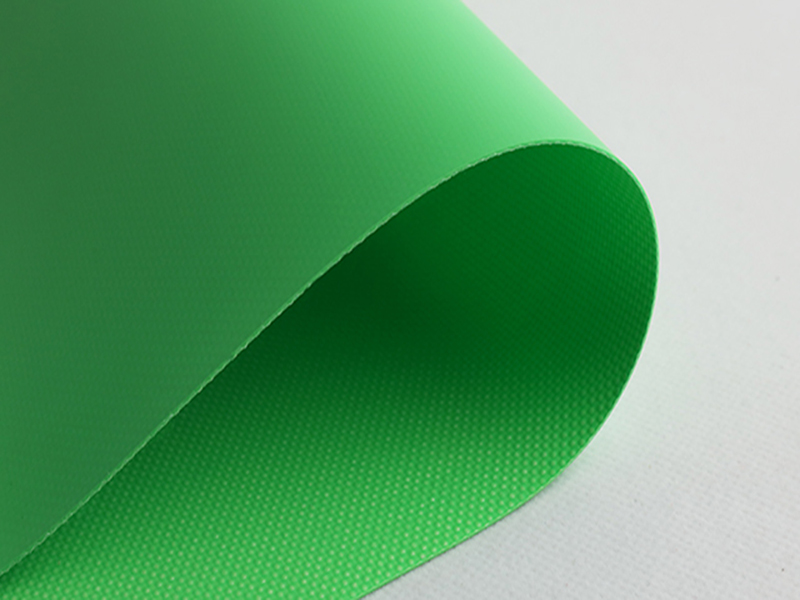

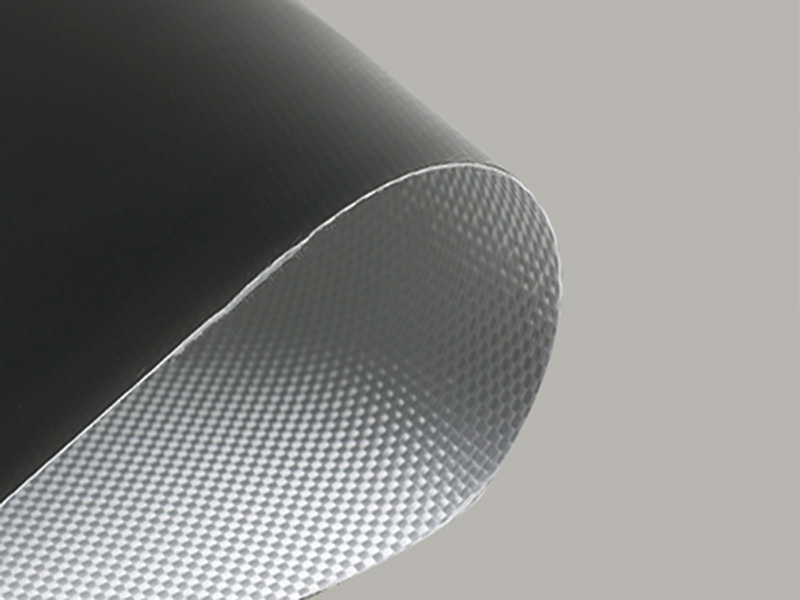

2. Tensile strength: The tarpaulin must bear various tensions during use. For example, when it is fixed, it will be tensioned: it will be subjected to additional forces such as wind, rain and saving during use. Despite these external forces, they are still required to maintain their original shape and not easily deform. This requires the tarp to have a higher tensile strength, and there should not be too much difference in tensile strength in the warp and weft directions. In particular, the tensile strength of large tents for inflatable buildings is extremely important. Generally, the base fabric is made of high-strength polyester, vinylon and other long-fiber fabrics. It is waterproof and finished by vinyl chloride resin and chlorosulfonated polyethylene resin. The strength of the product is mainly determined by the strength of the fiber material and the density of the fabric.

3. Elongation leather and dimensional stability: As eaves tents and large tents, it is often used under tension. The fabric extension should not be too large, and its dimensional stability is determined by the creep characteristics of the material.

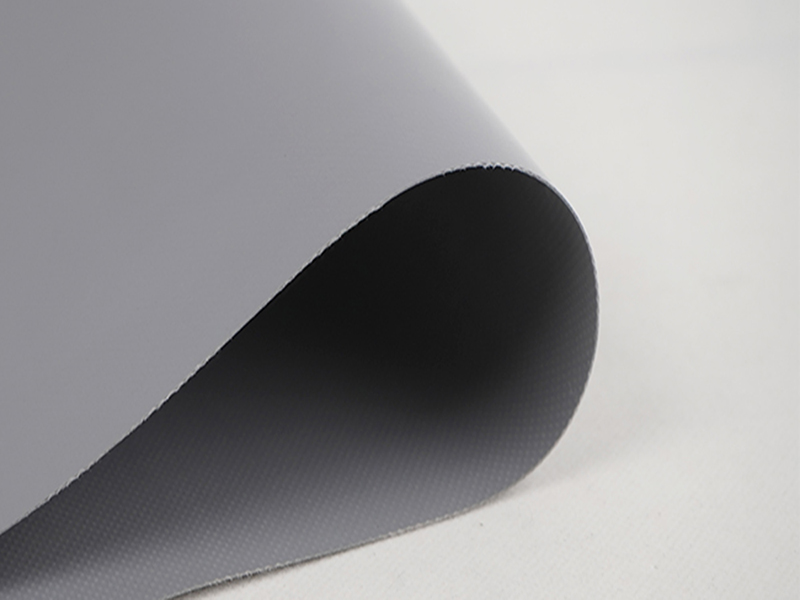

4. Tearing strength: The damage of the tarp is mainly caused by tearing, so the tearing strength is an important indicator of the tarp. The tear strength is related to whether the tarpaulin will break due to the action of flying foreign objects or expand to the surroundings after forming a hole for some reason, forming a large structural crack. Therefore, when the tension is high. Not only is the tarp cloth required to have high tensile strength, but it is also required to have high tear strength.

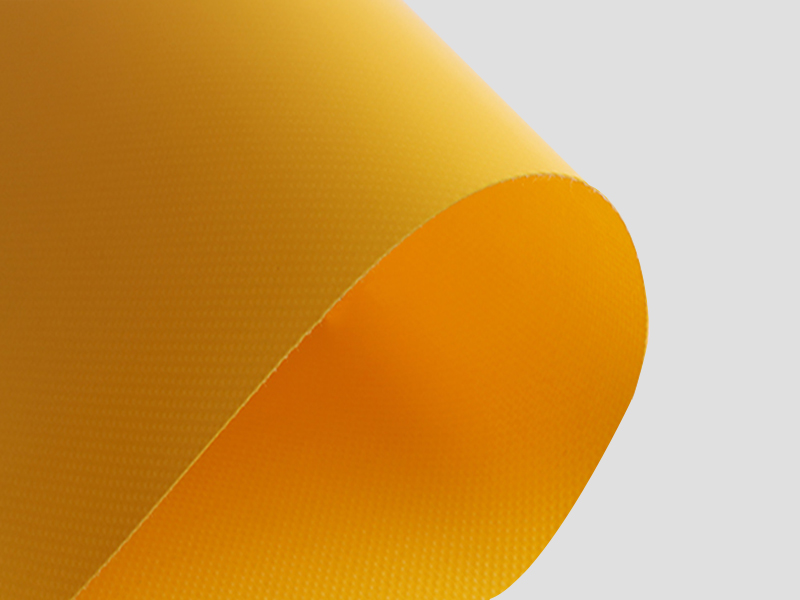

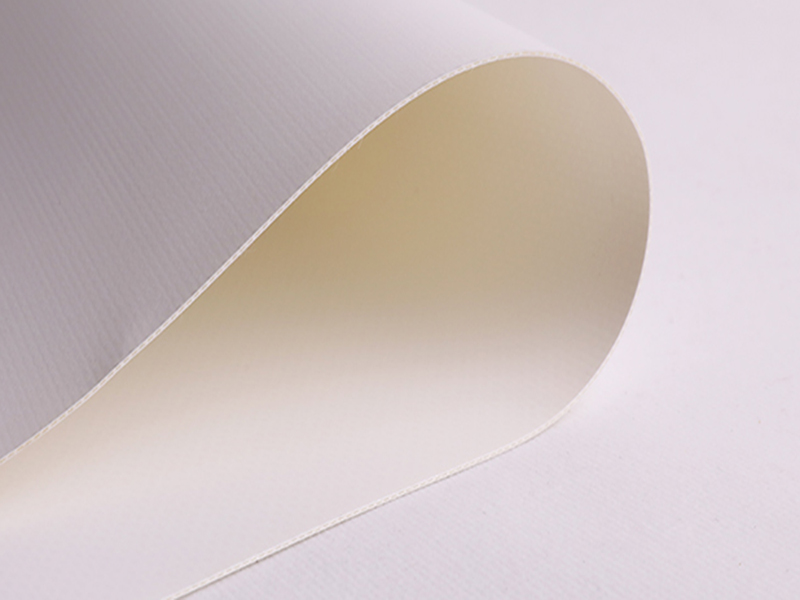

5. Water resistance: Water resistance is an important characteristic of tarpaulin. Through dipping and finishing, the vinyl chloride fat is filled in the gaps of the fabric tissue to form a coating film. If the amount of resin adhesion per unit area exceeds a certain level, water resistance is not a problem. If the coating film is thin, the coating film is easy to crack when it is bent, rubbed or the surface is worn, which may cause muddy water.

6. Flame retardancy: From the safety of use, the tarpaulin is required to have good flame retardancy. Flame retardancy can be obtained by selecting flame retardant fiber and flame retardant base fabric. It can also be achieved by adding flame retardant to the coating agent. The amount of flame retardant added is directly related to the flame retardant effect.

In addition to the above-mentioned performance requirements, the tarpaulin also requires superior cold resistance, heat resistance, tarpaulin, creep resistance, repeated fatigue resistance, abrasion resistance, and bending resistance.