The color of the projection screen The currently used projection screen colors are divided into white plastic screen and gray plastic screen.

1. The white plastic screen can truly reproduce the color and saturation of the projected picture. The contrast of the white plastic screen is accurate and natural. Since the gain of the white plastic screen is 1, there is no change to the projected picture, but the real reproduction and restoration. Therefore, it is suitable for high-contrast liquid crystal machines, which have bright colors and high color saturation. The white screen can accurately reproduce these advantages.

2. The gray plastic screen can increase the contrast of the projected picture, and the color transition will be deeper. It is equivalent to a negative gain, but the gray plastic screen can increase the gray scale and color gamut of the picture. Because the projector of the DLP machine has high sharpness and less color transition, it can be supplemented by these advantages of the gray plastic screen. The black level of the projection screen of the DLP machine behind the gray plastic screen will be deepened, and the gradation from black to white will be increased, reducing the fatigue of people watching for a long time.

Among them, the different projection screen materials are mainly divided into traditional white screens, soft screens, fiberglass screens, and sound-transparent screens in terms of visual manifestation.

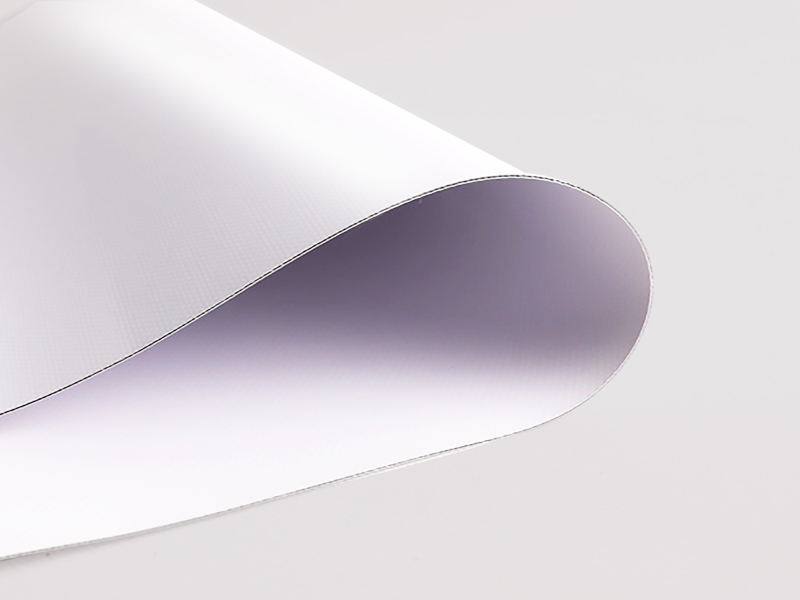

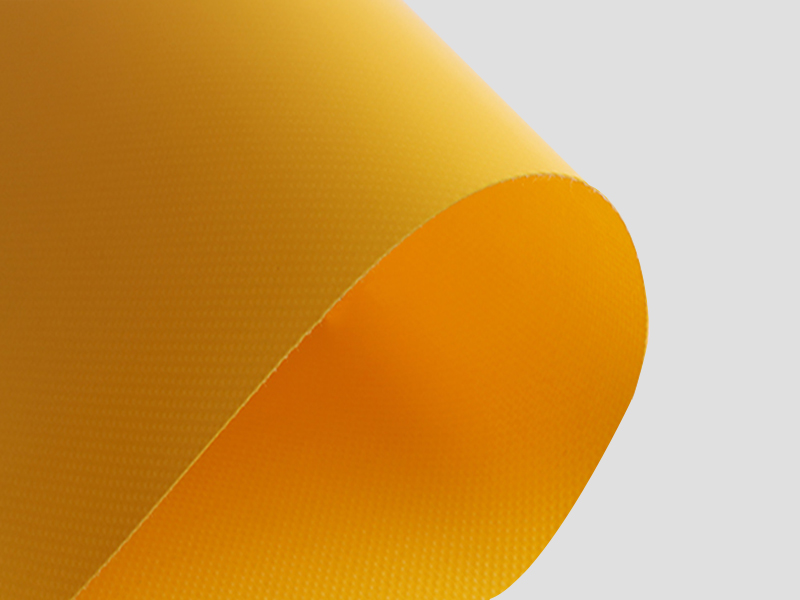

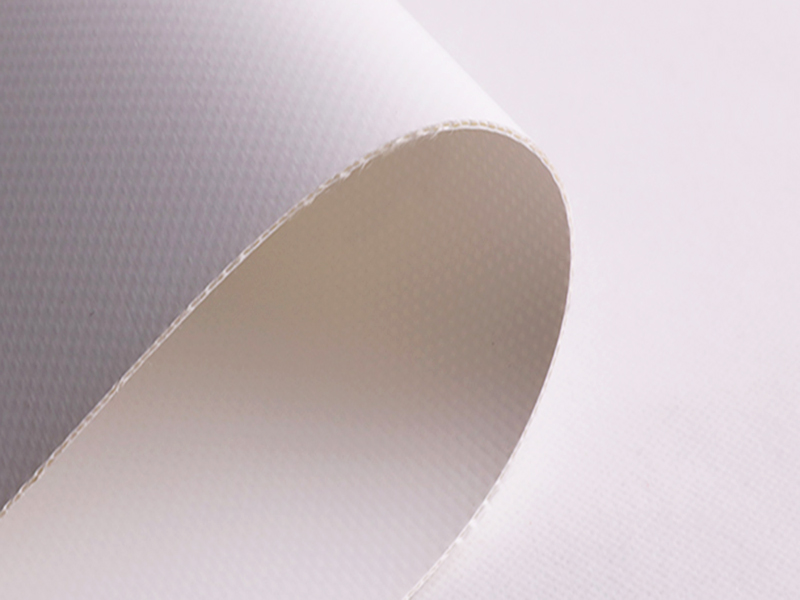

1. White screens are generally made of hand-drawn screens, which is the most common one, and the material is mainly white plastic cloth bottom.

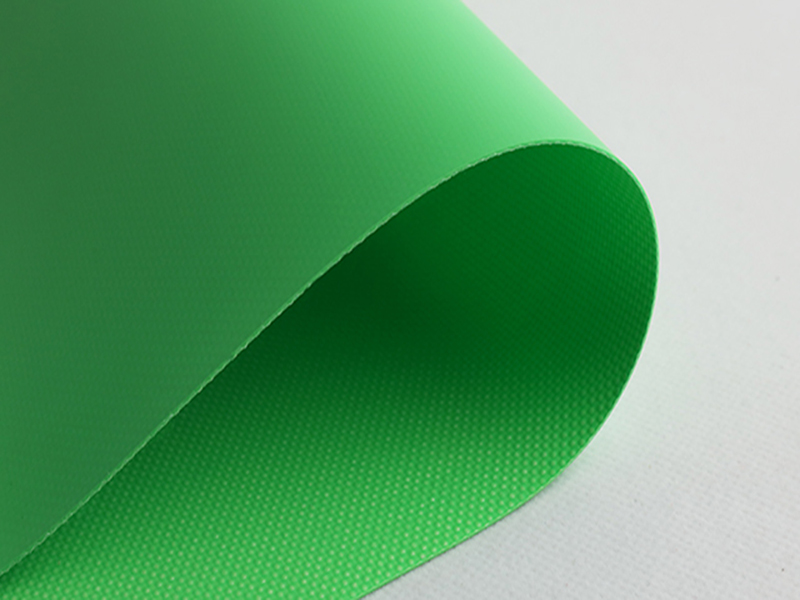

2. The soft curtain is composed of very thick imaging soft PVC (TS-PVC), also known as bottomless fabric curtain. It can restore colors truly, clearly and optimally, with good contrast levels. Since the soft curtain has no bottom fabric, it must be made into an electric wire-drawing screen to be flat, with high production technology and high cost. And if it is made into a fixed frame screen, the cost can be slightly lower.

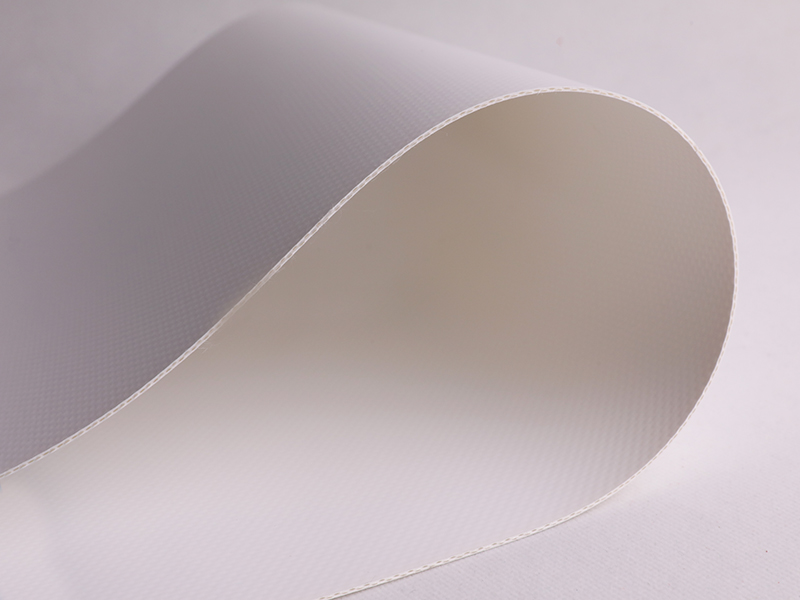

3. The glass fiber curtain uses a glass fiber woven base cloth instead of the traditional white plastic cloth base, which makes the image have a qualitative leap. In addition to faithfully reproducing colors. The glass fiber curtain will not be curled in winter and will not wrinkle in summer, so the life span is very long, and the flatness is not good. Can be made into any form of curtain. The cost of an electric screen made of glass fiber curtain is lower than that of a wire-drawn screen.

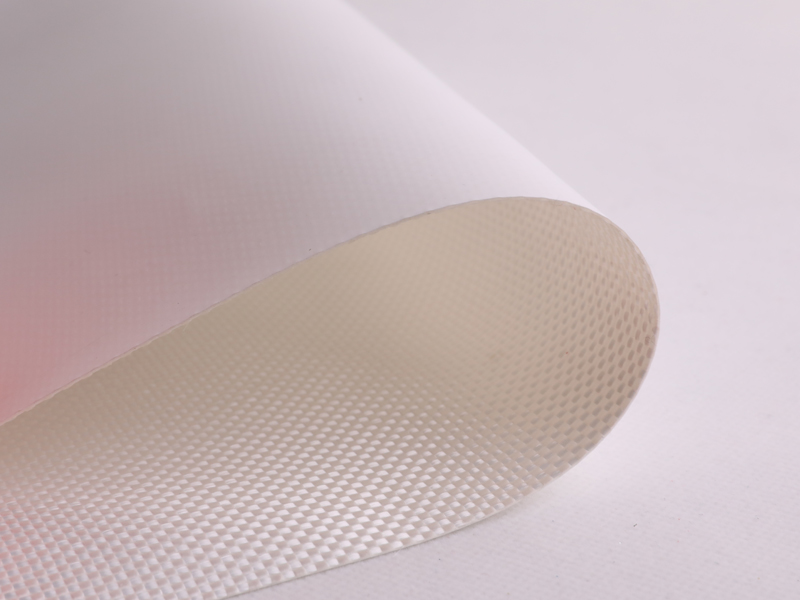

4. The sound-transmitting curtain, as its name implies, is a curtain that can transmit sound. The sound can pass through the back of the curtain and is well transmitted. The transparent sound screen is mainly used by customers who have high requirements for sound effects. When using it, the center of the sound system is usually hidden behind the screen. When the movie was showing, the sound came from behind the screen, as if it were the pronunciation of a real person in the movie. Therefore, the sense of presence is very strong. Basically, the sound-transmitting curtain can be made into various types of curtains, but if it is made into an electric curtain, it needs to be made into a cable curtain because there is no base cloth.