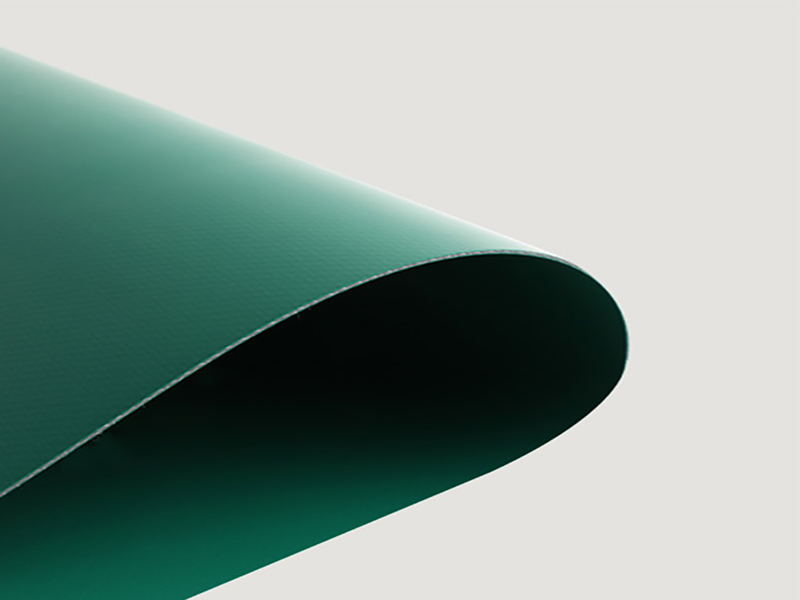

There are many kinds of tarpaulins in life, and their functions are also different. However, according to plastic tarpaulin wholesalers, the materials used when making tarpaulins are also required. White polyethylene tarpaulin is prone to discoloration after long-term use, which has a certain impact on its beauty and practicability. Then, many people cannot help but ask, what should be done to avoid this What happened? Let's take a look at what the professionals of Chongqing tarpaulin manufacturers say.

1. After cleaning the tarpaulin, apply toothpaste or powder made of white chalk on its surface, apply it evenly, and then dry it to prevent it from changing.

2. After cleaning the tarp, remember to cover the tarp with white paper when drying, and tear it off after drying to prevent discoloration.

3. In normal use, please also pay attention to avoid contact between white tarpaulin and carbon ink and other items that are difficult to clean.

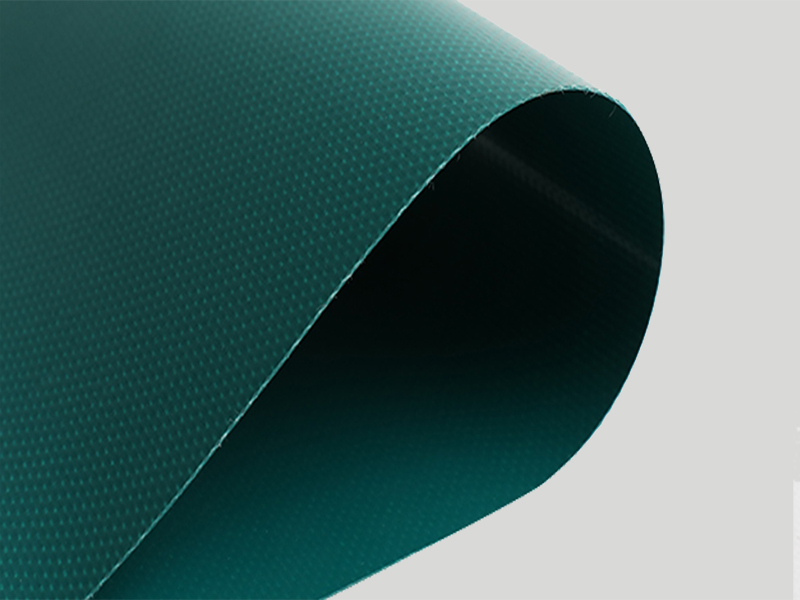

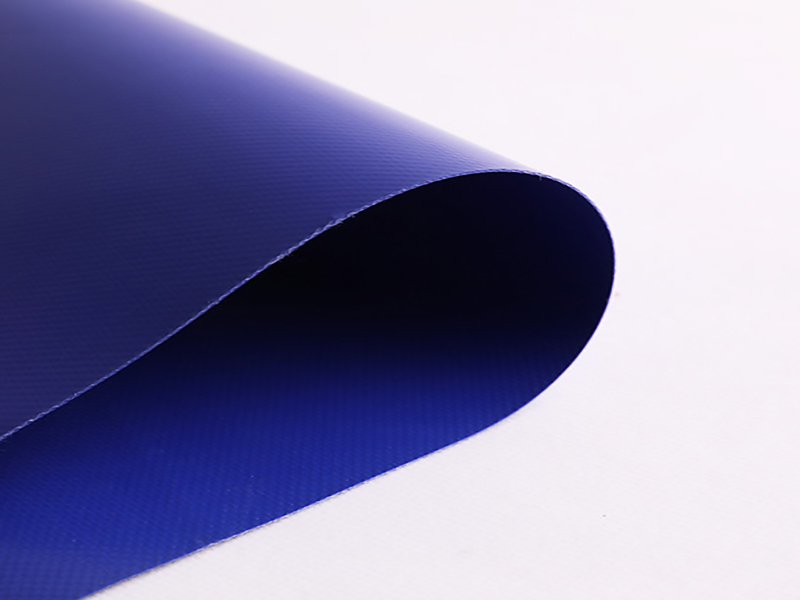

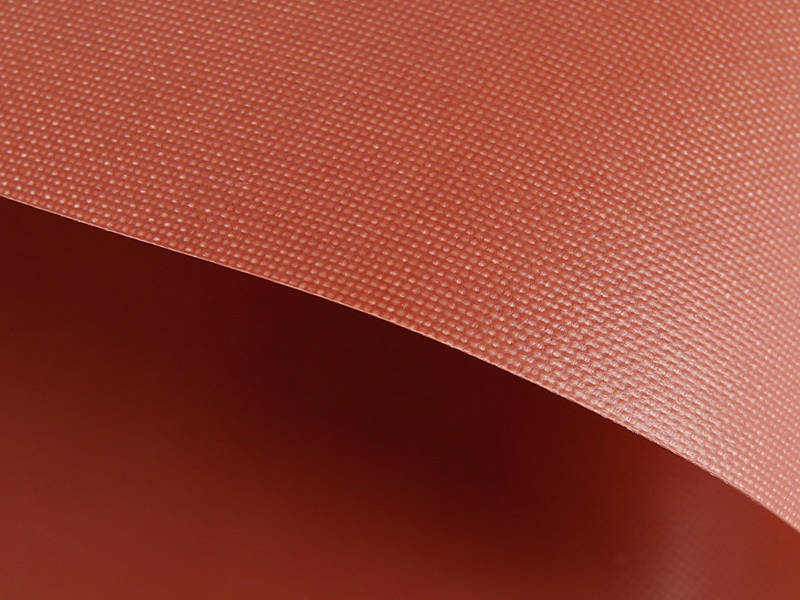

It is also a kind of tarpaulin, and it is often different in material. If the material used in the production of plastic tarpaulin is different, there will be some performance differences when it is used, except that it is in In addition to the material aspect, there is one more thing to pay attention to its performance in the production process. If only good production materials are used without a good production process, then the plastic tarpaulin will not have a good quality performance.

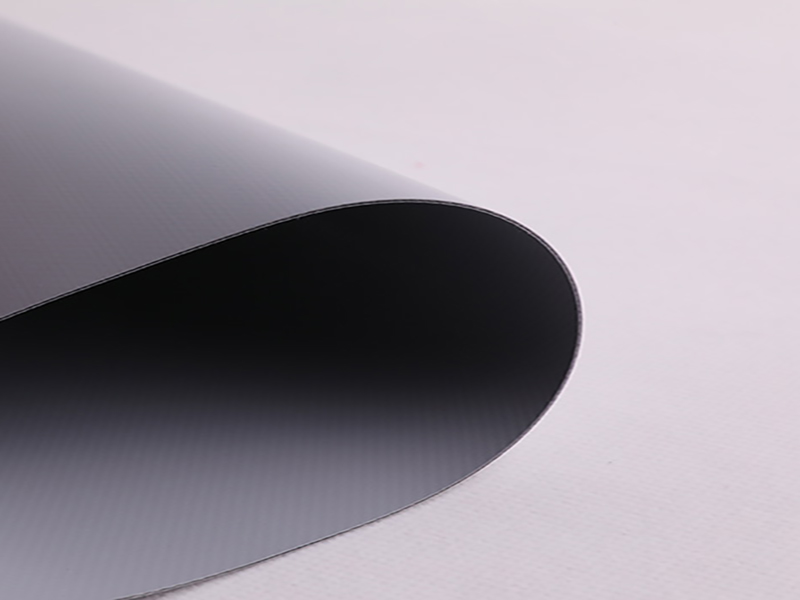

Established in 2001, Zhejiang Xingyida Reinforced Material Co., Ltd has become one of the leading manufacturers of coated fabrics and industrial textiles in China. The main products are architectural membranes, tarpaulins, awnings, tent material, inflatable fabrics and industrial base fabrics. Our manufacture plant, located in Haining City, 100km apart from Shanghai, covers an area of 25, 000 square meters and enjoys great convenient traffic with two national highways nearby.