Inflatables are in demand, thanks to advanced technologies that create higher quality products and new applications.

There was a time when consumers viewed inflatable products as bargain-basement cousins to rigid objects. Think of the air mattress rolled out on the bedroom floor for a middle-school sleepover or the discount-store blow-up swimming pool in the backyard. Their lifespans were measured in days.

Inflatables for sporting events have gotten bigger, better and bolder, and custom projects like this one by All-Star Inflatables Inc. of Dallas, Texas, are especially popular among football teams that want to outdo their rivals. Photo: All-Star Inflatables.

That rap obscures the fact that quality inflatables are legitimate structures, and the companies manufacturing and selling them have been in business for decades. What’s changed is the rapid expansion in the types of structures that have “gone inflatable,” putting them in the public eye like never before, as well as the developing technologies making new applications possible.

As inflatables have grown in popularity , consumers have begun to discover that they can be equal to a rigid alternative—and often offer superior qualities, such as portability. Ever try to pack a 10-by-20-foot billboard in a duffel bag? Inflatables for recreation, entertainment, athletics and other applications are definitely on the rise.

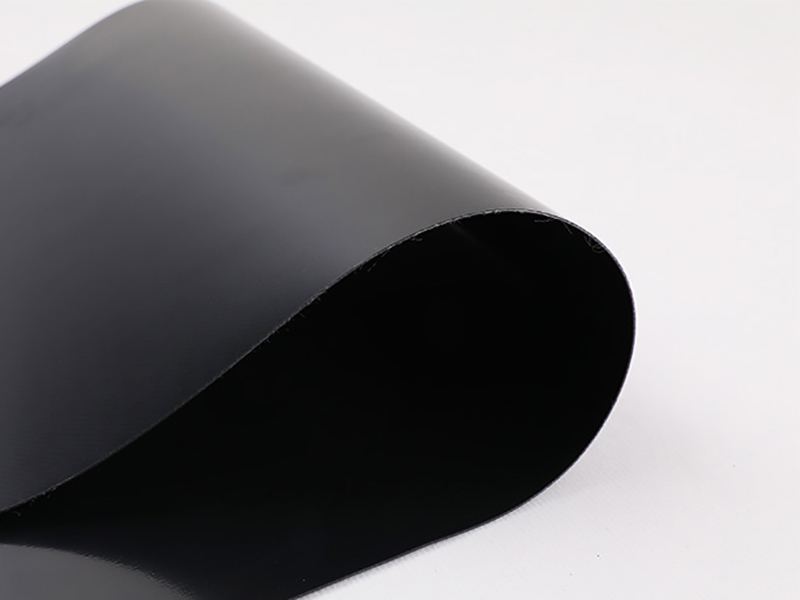

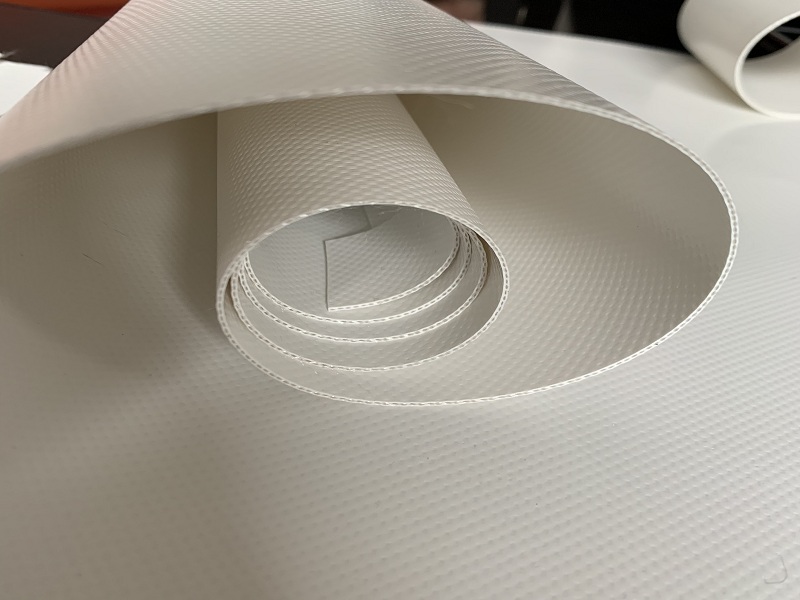

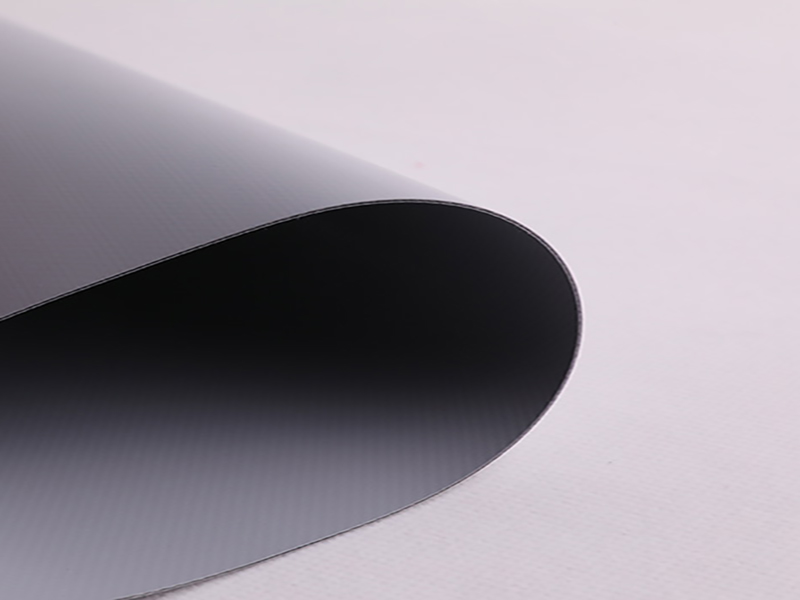

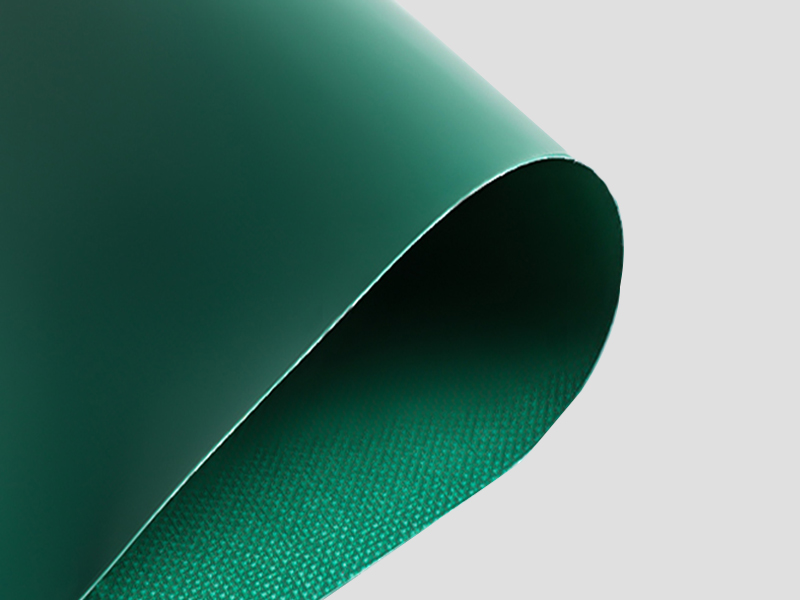

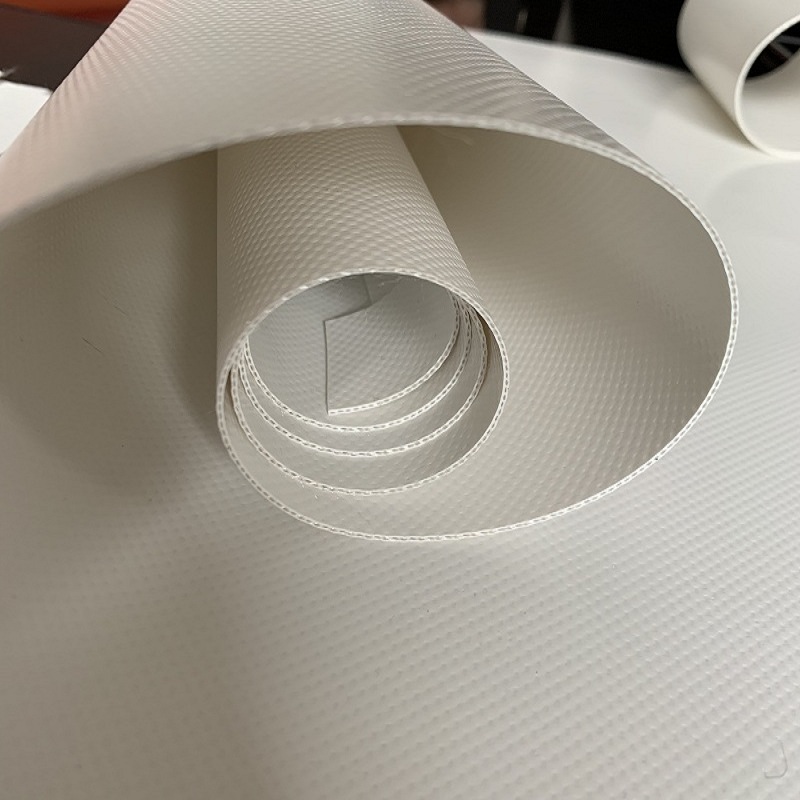

Established in 2001, Zhejiang Xingyida Reinforced Material Co., Ltd has become one of the leading manufacturers of coated fabrics and industrial textiles in China. The main products are architectural membranes, tarpaulins, awnings, tent material, inflatable fabrics and industrial base fabrics. Our manufacture plant, located in Haining City, 100km apart from Shanghai, covers an area of 25, 000 square meters and enjoys great convenient traffic with two national highways nearby.